Will Colour Blindness Fail a Medical Board for Electrical Trainee Roles?

- Technical review: Thomas Jevons (Head of Training, 20+ years)

- Employability review: Joshua Jarvis (Placement Manager)

- Editorial review: Jessica Gilbert (Marketing Editorial Team)

- Last reviewed:

- Changes: Initial publication covering medical board assessments, colour vision testing methods, international standards, and sector-specific requirements for electrical trainees.

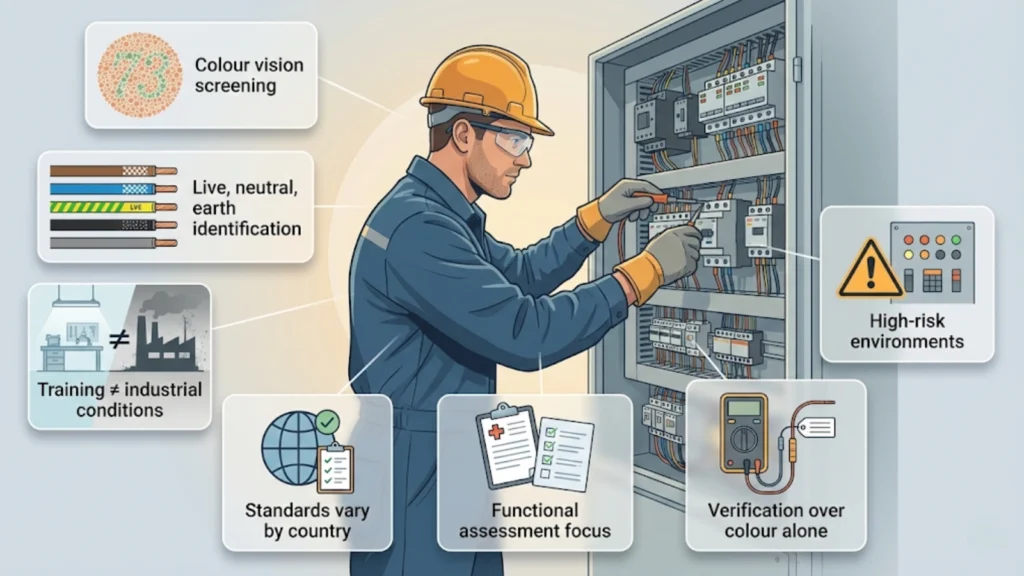

If you’re researching whether colour vision deficiency will prevent you from working as an electrical trainee, particularly in heavy industry, shipyards, or rail, you’re asking the right question at the right time. Here’s the thing: colour blindness doesn’t automatically disqualify you from electrical work, but it can lead to role-specific restrictions in safety-critical environments where the consequences of misidentifying a conductor or signal could be fatal. Medical boards assess fitness for specific duties, not whether you’re capable of learning the trade. That distinction matters, because you can qualify through UK electrical training and qualifications and still face employment restrictions when occupational health teams evaluate site-specific risks. This isn’t about discrimination or outdated policies (though some exist). It’s about whether you can safely identify colour-coded conductors, alarms, and lock-out/tag-out systems under the specific conditions of that workplace, low light, grime, operational pressure, without relying on verification tools that might not always be available. Outcomes vary wildly by employer, sector, country, and the severity of your colour vision deficiency, which is why understanding what medical boards actually assess, what “failing” typically means, and what your options are if you’re concerned, helps you make informed decisions before investing years in training for roles you might be restricted from entering.

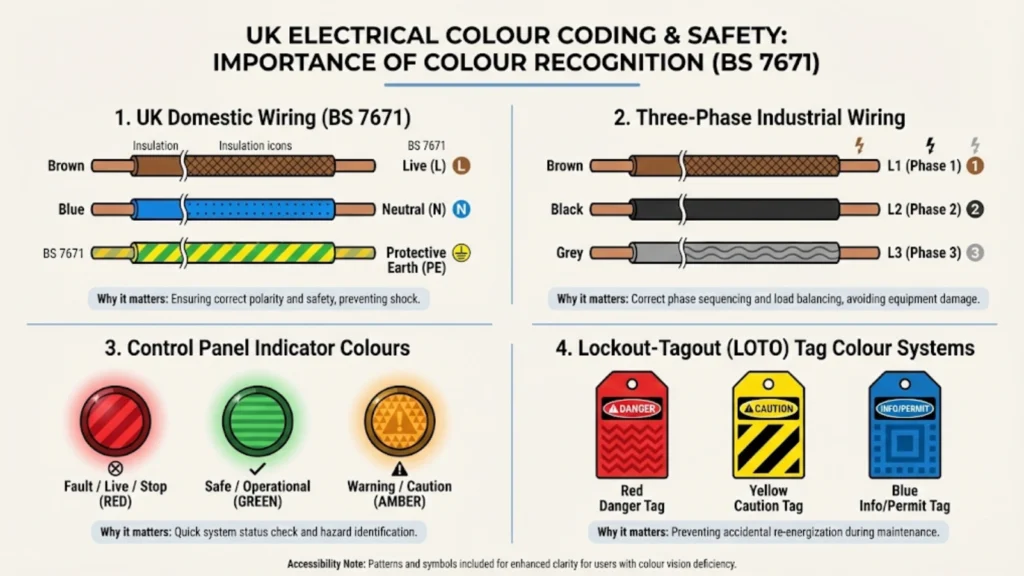

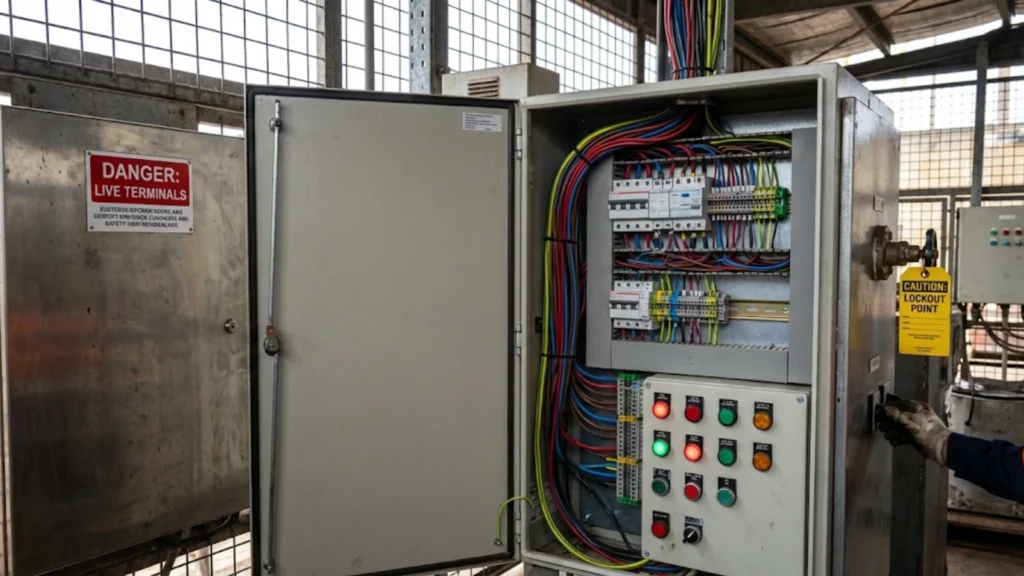

Why Colour Vision Is Assessed in Electrical Roles

Colour vision isn’t assessed because employers are being pedantic. In electrical work, particularly in industrial, rail, shipyard, and heavy-industry settings, colour coding is a primary safety control, not a convenience. Electrical systems rely on standardised colour identification for phase conductors (brown for live, blue for neutral, green-yellow for earth in the UK), and errors here pose immediate electrocution or fire risks. High-voltage environments and control rooms use bi-colour or tri-colour LED systems to indicate “Live,” “Safe,” or “Fault” states, where distinguishing red from green under poor lighting or at distance determines whether you proceed or isolate. Lock-out/tag-out (LOTO) procedures and safety signage often use colour as the sole differentiator for hazardous zones, especially in maritime, nuclear, and rail sectors where verbal confirmation isn’t always possible due to noise, distance, or operational constraints.

Here’s what makes industrial environments different from domestic work: environmental factors. Shipyards, mines, and offshore platforms operate under poor lighting, with components obscured by grime, paint overspray, or environmental conditions where “slight” colour confusion becomes a high-risk factor. You might need to identify a live conductor by colour alone with no opportunity to test, verify, or ask for confirmation. That’s the scenario occupational health teams are assessing, not whether you can distinguish colours in ideal conditions with unlimited time.

Thomas Jevons, Head of Training with over 20 years’ experience, explains the practical reality:

"The Ishihara test screens for red-green deficiency, but it doesn't tell you if someone can actually do the job safely. I've known electricians with mild CVD who've worked decades in domestic settings where they verify everything with testers anyway, good practice regardless of colour vision. The issue arises in safety-critical environments where you might need to identify a live conductor by colour alone under poor lighting with no testing opportunity. That's when functional assessments matter more than screening results."

Thomas Jevons, Head of Training

The assessment exists because employers have risk management obligations under health and safety frameworks. In the UK, the Health and Safety at Work Act requires employers to ensure, so far as reasonably practicable, the safety of employees and others. Allowing someone who cannot reliably distinguish red from green to work on live electrical systems in poor lighting without verification tools available creates foreseeable risk. That’s not discrimination under the Equality Act 2010, it’s operational safety, provided the employer can demonstrate that colour vision is an essential job function and that no reasonable adjustments can mitigate the risk.

Training vs Employment Medicals: The Critical Distinction

This is where confusion happens, and honestly, where candidates feel misled. Training providers for electrical qualifications, apprenticeships, Level 2/Level 3 courses, NVQs, do not typically impose medical exclusions for colour blindness. Their focus is on skill acquisition and competency demonstration, not fitness for specific employment. You can complete an electrical engineering degree, an apprenticeship, or a City & Guilds qualification with colour vision deficiency because training environments can accommodate it with proper lighting, labelling, verification time, and supervised practice.

Awarding bodies (City & Guilds, Pearson, SQA) grant certifications based on theoretical and practical competency against qualification criteria. They’re not assessing medical fitness for employment. That assessment happens separately when you apply for jobs, particularly in heavy industry, where employers conduct occupational health screenings to determine whether you can safely perform duties in their specific environment. This is the disconnect that causes frustration: you were allowed to train, you passed all assessments, you hold valid qualifications, and then an employer’s medical board restricts or denies site access based on colour vision.

Here’s the thing: qualification doesn’t equal site access. These are separate gatekeeping processes. The training provider assesses whether you can demonstrate competence under controlled conditions. The employer’s occupational health team assesses whether you can maintain that competence under their operational conditions, which might include poor lighting, time pressure, inability to use test equipment due to live-working protocols, or environmental factors that make colour identification critical.

Some professional bodies add a middle layer. The Joint Industry Board (JIB) and Electrotechnical Certification Scheme (ECS) issue cards that bridge training and employment, and some card grades require colour vision testing as part of the application process. This varies by card type and employer requirements, but it creates another potential restriction point after qualification but before employment.

To be fair, the training-employment gap needs better communication. If you’re considering becoming a qualified electrician UK and have any colour vision concerns, researching employer medical requirements in your target sector before committing years to training helps avoid devastating surprises. Occupational health clinics can assess whether your specific type and severity of CVD would likely cause issues in electrical roles, giving you information to make informed decisions about which sectors to pursue.

Understanding Medical Boards vs Occupational Health Screenings

The terms “medical board” and “occupational health screening” get used interchangeably, but they’re different assessment models with different consequences. Understanding which you’re facing helps manage expectations.

Medical boards are formal, often multi-disciplinary panels convened for high-stakes employment in sectors like defence, rail, maritime, or public sector undertakings (PSUs). They evaluate overall fitness against standardised criteria, typically with pass/fail orientations and comprehensive examinations beyond just occupational health. Medical boards have authority independent of the hiring manager, they can veto employment decisions even if you’ve been offered the role subject to medical clearance. These are more common in India’s PSU sector, UK rail and maritime industries, and US federal/defence contractors. The panel might include multiple physicians, occupational health specialists, and safety representatives who review your medical history, conduct physical examinations, and make binding decisions about fitness for duty.

Occupational health screenings are employer-initiated assessments focused on job-specific health risks. They’re often less formal than medical boards, conducted by a single occupational health physician or nurse, and emphasise functional capacity, risk mitigation, and compliance with health and safety regulations rather than broad eligibility. These screenings are more common in commercial electrical work, construction, and private-sector heavy industry. The outcome is usually a recommendation to the employer rather than a binding decision, though employers typically follow OH advice due to liability concerns.

Both can assess colour vision, but the approach differs. Medical boards tend toward standardised testing protocols with defined pass/fail thresholds, often using only Ishihara plates without secondary functional assessments. Occupational health screenings are more likely to conduct risk-based evaluations where failing the screening test triggers a conversation about functional ability, accommodations, and role-specific requirements rather than immediate disqualification.

The practical difference: if you’re facing a medical board for a PSU shipyard trainee role, expect a more rigid assessment with less flexibility. If you’re undergoing occupational health screening for a commercial electrical contractor, expect more emphasis on whether adaptations can mitigate risks for the specific role you’ll be doing.

Shipyards & Industrial Sites: Formal Assessment Processes

In large-scale engineering environments, defence shipbuilding, maritime, heavy manufacturing, rail infrastructure, utilities, the medical board or occupational health process follows a tiered assessment model designed to balance safety with fairness.

Tier 1: Initial Screening

The Ishihara test is standard. You’ll view 38 plates (sometimes fewer in abbreviated versions) containing coloured dots forming numbers or patterns. If you can’t identify the numbers in a certain percentage of plates (thresholds vary, but typically failing more than 3-5 plates indicates red-green deficiency), you “fail” the screening. Here’s what that actually means: you’ve been identified as having colour vision deficiency, not that you’re automatically unfit for the role.

Tier 2: Functional Assessment (The Safety Case)

Some employers, particularly those with robust occupational health teams, conduct secondary functional tests if you fail Ishihara screening. This might involve:

- Wire sorting tasks: Identifying actual electrical cables under various lighting conditions to see if your CVD is “clinically significant” for that environment.

- Lantern tests: Viewing coloured lights at distance to simulate signal identification tasks in rail or maritime contexts.

- CAD tests (Colour Assessment and Diagnosis): More sophisticated colour vision testing that assesses severity and functional impact rather than just screening for deficiency.

- Workplace simulation: Some shipyards use trade-specific tests like identifying shipboard cabling or control panel indicators under operational conditions.

Because trainees work under supervision, some boards allow entry with restricted clearance. This might look like: “Fit for trainee electrician role provided all colour-dependent tasks are verified by qualified supervisor” or “Cleared for electrical installation work; restricted from independent testing and fault-finding.” This acknowledges that supervised learning environments can mitigate risks that wouldn’t be acceptable for independent practitioners.

Tier 3: Role-Specific Restrictions

Medical boards rarely bar candidates from entire companies. Instead, they implement site-wide or task-specific exclusions: “No high-voltage live working,” “Deep-hull installations require supervisor verification,” “Cleared for mechanical installation; restricted from control panel work.” This allows employment while managing risks. The variability is massive.

Joshua Jarvis, Placement Manager, explains the frustration candidates face:

"Two shipyards might have completely different medical standards even though they're in the same sector. One might accept functional testing showing you can identify cables safely; another might rigidly apply Ishihara pass/fail criteria. There's no consistency, which frustrates candidates who feel they're being judged arbitrarily. Best approach is asking specific questions during recruitment: 'What colour vision test do you use?' 'Are accommodations considered?' 'What does restricted clearance mean for career progression?'"

Joshua Jarvis, Placement Manager

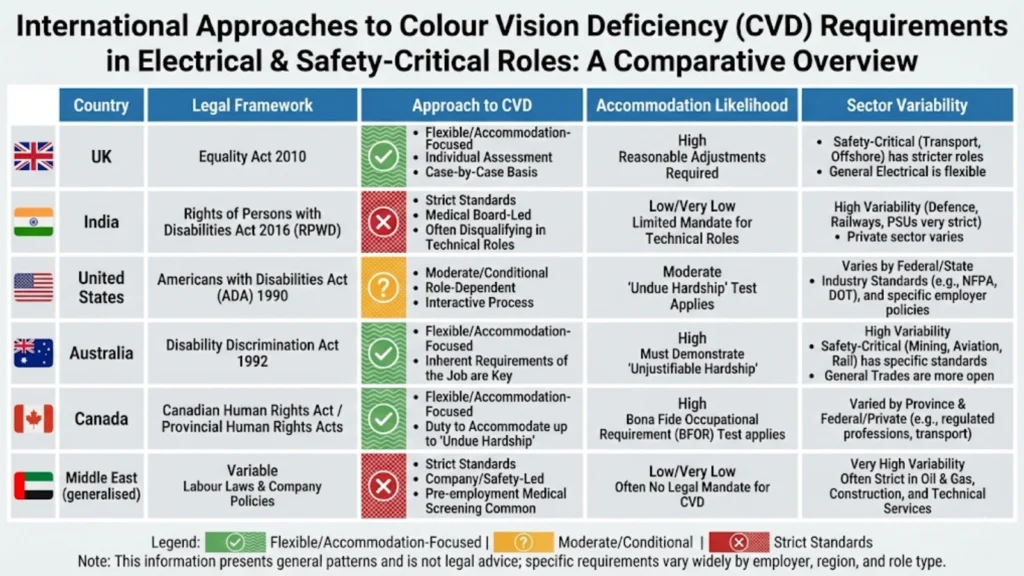

Country Differences: UK, India, US, and Beyond

How colour vision deficiency is assessed and accommodated varies dramatically by country, driven by legal frameworks, cultural approaches to disability, and sector-specific regulations.

United Kingdom

Framework: Health and Safety at Work Act 1974, Equality Act 2010

Approach: Task-based risk assessment with emphasis on reasonable adjustments

The UK requires employers to assess whether reasonable adjustments can mitigate risks before excluding anyone on medical grounds. This means proving colour vision is genuinely critical for that specific role and that no accommodation exists without creating unacceptable safety risks. The burden is on the employer to demonstrate this, not on the candidate to prove they can work safely.

In practice, this creates variability by sector. Domestic electrical contractors often accept colour vision deficiency with adaptations like labelling, adequate lighting, and verification protocols. Heavy industry, particularly rail, has more stringent requirements. Network Rail and Rail Safety and Standards Board (RSSB) use two-step testing: Ishihara screening followed by lantern tests for safety-critical roles. Recent revisions to rail colour vision standards (2024-2025) have moved toward more functional assessments recognising that Ishihara alone doesn’t predict workplace performance.

There’s no absolute bar in UK law, but employers can exclude if they demonstrate it’s a proportionate means of achieving a legitimate aim (safety). Medical boards in UK shipyards, offshore, and nuclear sectors tend toward conditional clearance or restricted duties rather than outright rejection, though this varies by employer risk appetite.

India

Framework: PSU Medical Manuals, Factory Act regulations, specific sector standards

Approach: Stricter regulatory thresholds with less accommodation flexibility

Public Sector Undertakings (Cochin Shipyard, Mazagon Dock, Bharat Heavy Electricals Limited, Indian Oil Corporation) often maintain rigid visual standards with limited room for adjustment. Medical boards in PSUs typically apply pass/fail criteria where colour vision deficiency, even mild red-green deficiency, can disqualify candidates for technical electrical roles.

The standards vary by PSU and role. Some allow colour vision deficiency in non-technical or administrative functions but exclude from field engineering roles. Defence and railway PSUs tend to be strictest. Private sector companies in India have more flexibility and may conduct functional assessments, but competitive job markets mean they often default to excluding CVD candidates when they have sufficient non-CVD applicants.

Cultural factors play a role. Candidates report that medical boards in India PSUs are less likely to engage in accommodation discussions, viewing medical standards as non-negotiable safety requirements. Appeals processes exist but rarely succeed unless the initial diagnosis was incorrect.

United States

Framework: Americans with Disabilities Act (ADA), OSHA regulations

Approach: Essential job functions model with individualized assessment

The US requires employers to prove colour vision is an essential function of the specific job and that no reasonable accommodation exists without creating undue hardship. This shifts burden to employers to justify exclusions. The EEOC (Equal Employment Opportunity Commission) guidance on visual disabilities requires individualized assessments, not blanket exclusions based on diagnosis alone.

In practice, US employers conduct functional assessments more frequently. If you fail Ishihara screening, they’re more likely to test whether you can perform actual job tasks safely using workplace simulations or alternative testing methods. Safety-critical roles in utilities, nuclear, and petrochemical still maintain strict standards, but the legal framework requires proving you cannot perform essential functions even with accommodation.

Federal contractors and defence industry follow stricter protocols due to security clearance and safety requirements, but even these increasingly use functional testing rather than relying solely on screening tests.

Australia

Framework: Work Health and Safety Act, Disability Discrimination Act

Approach: Similar to UK with risk-based assessment and reasonable adjustments

Australian employers must demonstrate inherent job requirements before excluding on medical grounds. Electrical licensing bodies (state-specific) don’t typically impose colour vision requirements for licensure, leaving it to individual employers to assess. Mining, offshore, and rail sectors have stricter standards, often using lantern tests for roles involving signal identification. Commercial and domestic electrical work has fewer restrictions.

Canada

Framework: Canadian Human Rights Act, provincial occupational health and safety legislation

Approach: Accommodation to point of undue hardship

Similar to US, Canadian employers must accommodate disabilities unless it creates undue hardship (cost, health and safety risk). Provinces vary in electrical trade requirements. Some require colour vision testing for Red Seal certification in specific trades; others leave it to employer discretion. Oil and gas, mining, and utilities sectors have stricter assessments.

Middle East (UAE, Saudi Arabia, Qatar)

Framework: Ministry of Labour regulations, sector-specific standards

Approach: Varies by employer and nationality; less standardised than Western countries

Medical fitness certificates are required for work permits, and assessments vary by employer, project, and the medical centre conducting examinations. Major projects (oil and gas, infrastructure, defence) often follow international standards (UK HSE or US OSHA equivalents) with functional assessments. Smaller contractors might apply rigid screening without functional follow-up. Outcomes can depend on labour market conditions, when workers are scarce, accommodations increase.

What "Failing" a Colour Vision Test Usually Means

Here’s what candidates fear: total exclusion from electrical work forever. Here’s what usually happens: conditional clearance or role-specific restrictions.

Conditional Clearance means “Fit to work provided [X] condition is met.” Examples include:

- Must work under supervision of non-CVD qualified electrician for colour-dependent tasks

- Required to use verification tools (multimeters, voltage testers) for all conductor identification

- Specific labelling protocols must be followed in addition to standard colour coding

- Additional lighting requirements for workspace

- Restriction to daylight work hours only (not night shifts where lighting is poor)

These conditions recognise that CVD creates risk in specific contexts but can be managed with controls. You’re employed, but your work methods have additional requirements.

Restricted Duties means barred from certain tasks but cleared for others:

- No independent live-circuit testing or fault-finding

- Cleared for mechanical installation but not control panel work

- Can perform design, project management, CAD work but not field installation

- Approved for low-voltage domestic work but not high-voltage industrial

- Permitted in installation teams but not as testing/inspection electrician

This allows employment while acknowledging some tasks present unmanageable risks. Career progression might be affected, you might not reach senior roles requiring independent testing competence, but you’re not excluded from the trade entirely.

Alternative Task Allocation means moving to a different role within the company:

- Trainee electrician position shifted to electrical design or procurement

- Field role changed to workshop-based or office-based technical support

- Installation work redirected to project coordination or safety management

- Heavy industry role moved to non-safety-critical commercial work

This happens more often in large employers with diverse roles. The medical board says you’re not fit for the original role but suitable for alternatives.

Non-Deployment to Specific Environments means cleared for the role but cannot work in certain locations:

- Approved for electrical work but not offshore platforms

- Cleared for general duties but restricted from nuclear “Red Zones”

- Fit for shipyard work but not deep-hull confined spaces

- Authorised for substation work but not live-line maintenance

This recognises that environmental factors (lighting, inability to verify, operational pressure) create risks in some settings but not others.

To be fair, “fail” rarely means “go home and choose a different career.” It means “we need controls in place” or “this specific role doesn’t match your capabilities, but alternatives might.” The challenge is that medical boards don’t always communicate this clearly, and candidates interpret “unfit for this role” as “unfit for all electrical work.”

What to Do If You're Concerned About Colour Vision

If you have colour vision deficiency or suspect you might, here’s the practical approach:

Before Training: Get tested properly. Not the online tests, a proper occupational health assessment by an optometrist or ophthalmologist who can:

- Determine your specific type of CVD (protanopia, deuteranopia, tritanopia, severity)

- Conduct functional assessments relevant to electrical work

- Provide documentation you can use if needed

- Advise on which sectors might be more or less accommodating

This information helps you make informed decisions about which electrical pathways to pursue. If you have severe red-green deficiency, domestic electrical work might be more viable than shipyard heavy industry. If you have mild deficiency, you might be fine with adaptations.

During Recruitment: Ask specific questions before accepting offers or attending medical boards:

- What colour vision test do you use? (Ishihara only, or functional assessments available?)

- If I fail the screening test, what happens next? (Immediate rejection or secondary testing?)

- Are accommodations or adjustments considered for the specific duties I’ll perform?

- What does “restricted clearance” mean for this role? (Can I still progress, or am I permanently limited?)

- Can I provide external medical documentation if it demonstrates functional ability?

- Is there an appeals process if I disagree with the medical board decision?

These questions signal you’re informed and proactive without revealing whether you have CVD. Employers’ responses tell you whether they take a risk-based accommodation approach or rigid pass/fail exclusion.

Request the Medical Standards Document before the board meets. Many employers have written medical fitness standards for recruitment. Reading these beforehand shows you what thresholds they use and whether secondary testing is mentioned. If the document says “Must pass Ishihara test with no more than 2 errors” you know the standard. If it says “Adequate colour vision for safe task performance” there’s more flexibility.

Clarify the Offer Type: Distinguish between “offer subject to medical clearance” (they can withdraw if you don’t pass) and “conditional offer contingent on satisfactory medical” (similar but sometimes with appeal rights) versus “final appointment subject to formalities” (medical is usually less gatekeeping). Contracts matter. Read them carefully regarding medical assessment terms.

Don’t Self-Exclude Based on General Information: Online forum posts, generic career advice, outdated medical guidance, none of this tells you what a specific employer will decide. CVD severity varies, functional ability varies, employer standards vary. Someone saying “I failed a medical board” doesn’t mean you will, especially if they’re in a different sector, country, or severity category.

If You Fail an Assessment: Ask for specific reasons, what tasks they believe you cannot safely perform, whether functional testing is available, whether accommodations were considered, and whether appeals are possible. Medical boards sometimes make decisions based on rigid protocols without considering individual circumstances. Challenging these (respectfully, with supporting evidence) sometimes results in reassessment.

Consider Sector Alternatives: If heavy industry medical boards consistently restrict you, commercial electrical work, renewable energy installation, EV charging infrastructure, building services, these sectors have different risk profiles and might be more accommodating. Your electrical qualifications remain valid, you’re redirecting them to employers with different medical requirements.

Myths vs Reality

Myth: Colour blindness automatically disqualifies you from all electrical roles.

Reality: Many electricians with CVD work successfully with adaptations. Restrictions are role-specific and sector-specific, not trade-wide. Domestic and commercial electrical work has different requirements than safety-critical heavy industry.

Myth: Training programs exclude people based on colour vision.

Reality: Training focuses on skills and competency demonstration. Exclusions at the training stage are rare. The gatekeeping happens at employment, not education. You can qualify with CVD; site access is the separate question.

Myth: Failing Ishihara means total failure of the medical assessment.

Reality: Ishihara is a screening test, not a diagnostic or functional assessment. Failing it often triggers secondary testing (lantern tests, functional tasks, workplace simulation) or leads to restricted duties rather than exclusion. It identifies that you have CVD, not that you’re automatically unsafe.

Myth: Colour vision deficiency isn’t an issue in modern electrical work because everything’s labelled.

Reality: While labelling and verification are good practices, safety-critical tasks still involve scenarios where colour identification is the primary or only available safety indicator, particularly in emergency fault-finding, live working under time pressure, or environments where labels degrade (maritime, outdoor, harsh conditions). CVD remains relevant in these contexts.

Myth: Special glasses (EnChroma, etc.) will help you pass the medical board test.

Reality: Most industrial medical boards explicitly prohibit colour-correcting lenses during testing because they’re assessing your unaided functional ability. Additionally, these glasses don’t work for everyone, effectiveness varies by CVD type and severity, and relying on equipment that can be lost, damaged, or unavailable creates unacceptable risk in safety-critical environments.

Myth: If I have the electrical certificate/qualification, the medical is just a formality.

Reality: In heavy industry, medical boards have final authority over site access regardless of qualifications. Your NVQ Level 3, degree, or apprenticeship completion proves competency under training conditions. The medical board assesses whether you can maintain that competency under their operational conditions. These are separate approval processes.

Myth: It’s illegal to not hire someone for colour blindness.

Reality: If colour vision is an essential job function for safety and no reasonable accommodation exists without creating unacceptable risk, employers can legally restrict placement. In the UK (Equality Act), US (ADA), and similar frameworks, employers must prove this and explore accommodations first, but they’re not required to accept unsafe risk. Blanket exclusions without individualised assessment are more legally problematic than role-specific restrictions based on functional inability.

FAQs

Colour vision deficiency doesn’t automatically disqualify you from electrical work, but it does create role-specific and sector-specific challenges that you need to understand before committing to training or accepting employment offers. Medical boards assess functional fitness for specific duties under specific conditions, not whether you’re generally capable of electrical work in ideal circumstances. That distinction matters because the controlled, well-lit, supervised, time-unlimited conditions of training environments differ fundamentally from the operational pressure, poor lighting, independent decision-making, and inability-to-verify scenarios in safety-critical industrial work.

The outcomes you’ll face depend on: your specific type and severity of CVD (mild deuteranomaly has different implications than severe protanopia), the sector you’re pursuing (domestic electrical work has different risk profiles than shipyard heavy industry), the country you’re working in (UK task-based assessments differ from India PSU pass/fail boards), the employer’s approach to accommodation (some prioritise risk elimination through functional testing, others default to rigid screening exclusions), and your willingness to accept conditional clearance or restricted duties rather than insisting on unrestricted employment.

Here’s what you should do: get tested properly before training to understand what you’re dealing with. Research sector-specific medical requirements in your target industry. Ask employers specific questions about colour vision testing methods and accommodation policies during recruitment. Don’t self-exclude based on general information or forum posts, individual circumstances vary too much. If you fail a medical assessment, ask about functional testing, appeal rights, and whether restrictions are permanent or role-specific. Consider alternative electrical sectors if heavy industry consistently excludes you, your qualifications remain valid even if one sector’s medical boards restrict you.

The frustration many candidates feel comes from the training-employment gap, you were allowed to qualify, you passed all competency assessments, and then medical gatekeeping restricts employment in ways that feel arbitrary or discriminatory. That frustration is valid. But understanding the distinction between educational competency and workplace functional fitness, between screening tests and functional assessments, between total exclusion and conditional clearance, helps you navigate this process more effectively and make informed decisions about which electrical pathways align with your capabilities and the accommodations available in different sectors.

Call us on 0330 822 5337 to discuss electrical training pathways and what employers in different sectors typically require for medical fitness. We’ll explain qualification routes, sector differences, and realistic employment prospects based on your circumstances. No hype. No false promises. Just honest guidance from people who’ve supported hundreds of learners through training into employment across domestic, commercial, and industrial electrical sectors.

References

UK Frameworks & Guidance

- Health and Safety at Work Act 1974 – https://www.hse.gov.uk/pubns/priced/l24.pdf

- Equality Act 2010 guidance – https://www.gov.uk/guidance/equality-act-2010-guidance

- HSE Medical Aspects of Occupational Health – https://www.hse.gov.uk/pubns/ms7.htm

- IET Colour Vision in the Workplace – https://www.theiet.org/media/9460/colour-vision-in-the-workplace.pdf

- Network Rail Occupational Health User Guide – https://occupationalhealth.networkrail.co.uk/wp-content/uploads/2025/01/Network-Rail-Inhouse-Occupational-Health-Services-User-Guide-V1-January-2025.pdf

- RSSB Railway Medical Standards RS507 – https://www.rssb.co.uk/standards-catalogue/CatalogueItem/RS507-Iss-1

- RMT Colour Vision Testing Circular – https://www.rmt.org.uk/about/health-and-safety/health-and-safety-circulars/colour-vision-testing-within-the-rail-industry090424

- City St George’s Rail Colour Vision Testing – https://www.citystgeorges.ac.uk/news-and-events/news/2025/january/colour-vision-testing-train-drivers

US Frameworks & Guidance

- EEOC Visual Disabilities in the Workplace – https://www.eeoc.gov/laws/guidance/visual-disabilities-workplace-and-americans-with-disabilities-act

- ADA Resources – https://www.ada.gov/resources/lodging-guide

- Job Accommodation Network (JAN) Colorblind Accommodations – https://askjan.org/disabilities/Colorblind-Color-Vision-Deficiency.cfm

- OSHA Medical Surveillance – https://www.osha.gov/sites/default/files/publications/osha3162.pdf

- OSHA Colour Vision Interpretation – https://www.osha.gov/laws-regs/standardinterpretations/2004-01-29-0

International & Sector-Specific

- SOLAS Ireland Colour Vision FAQ – https://content.apprenticeship.ie/f/83224/x/11a3e964c4/solas_colour_vision_faq.pdf

- IOCL PSU Medical Standards (India example) – https://iocl.com/admin/img/UploadedFiles/LatestJobOpening/Files/ec2293fd0d344c1da55fdf9c2247a423.pdf

- NHPC Medical Standards (India PSU) – https://www.nhpcindia.com/assests/pzi_public/pdf_link/65d5c0e4b1738.pdf

- Colourblind Awareness Careers Guide – https://www.colourblindawareness.org/colour-blindness/living-with-colour-vision-deficiency/careers-and-the-workplace

Testing & Medical Information

- Ishihara Test Information – https://www.mdcalc.com/calc/10061/color-vision-screening-ishihara-test

- Colour Vision Testing Methods – https://mediprise.com/color-vision-testing-methods

- PMC Colour Vision Deficiency Research – https://pmc.ncbi.nlm.nih.gov/articles/PMC8917564

- PubMed Railway Colour Vision Study – https://pubmed.ncbi.nlm.nih.gov/24695202

- NCBI Colour Vision Tests – https://www.ncbi.nlm.nih.gov/books/NBK217823

Occupational Health References

- Scout Logic OH Screening – https://www.scoutlogicscreening.com/blog/what-is-occupational-health-screening

- OHS Online Medical Surveillance – https://ohsonline.com/articles/2021/09/01/medical-surveillance-vs-medical-screening.aspx

- K2 Occupational Health Fitness Assessment – https://www.k2occupationalhealth.com/everything-you-need-to-know-about-fit-for-work-medical-assessment

- US Drug Test Centers Vision Screening – https://www.usdrugtestcenters.com/occupational-health-services-vision-screening.html

Note on Accuracy and Updates

Last reviewed: 5 February 2026. This article addresses medical board assessments for electrical trainee roles based on current UK, international, and sector-specific standards as of early 2026. Medical standards, particularly in rail and maritime sectors, are subject to periodic revision. Colour vision testing protocols evolve as functional assessment methods improve. Individual employer requirements vary significantly even within the same sector. This guidance provides general information; specific medical fitness decisions are made by occupational health professionals assessing your individual circumstances against employer-specific criteria. We correct errors and refresh sources as regulations change. For medical advice about your specific colour vision deficiency, consult an optometrist or ophthalmologist with occupational health expertise.